S550MC Plates

- Home

- S550MC Plates

S600MC Plates

S600MC High Tensile Steel Plates, including offshore and structural grades, are high-performance carbon steel plates compliant with EN 10149-2 standards. These plates are available in hot-rolled and pressure vessel grades, and are supplied by stockists, dealers, and exporters in Mumbai, India. S600MC alloy steel plates are ideal for various industrial applications requiring high tensile strength and durability..

S600MC High Tensile Steel Plates

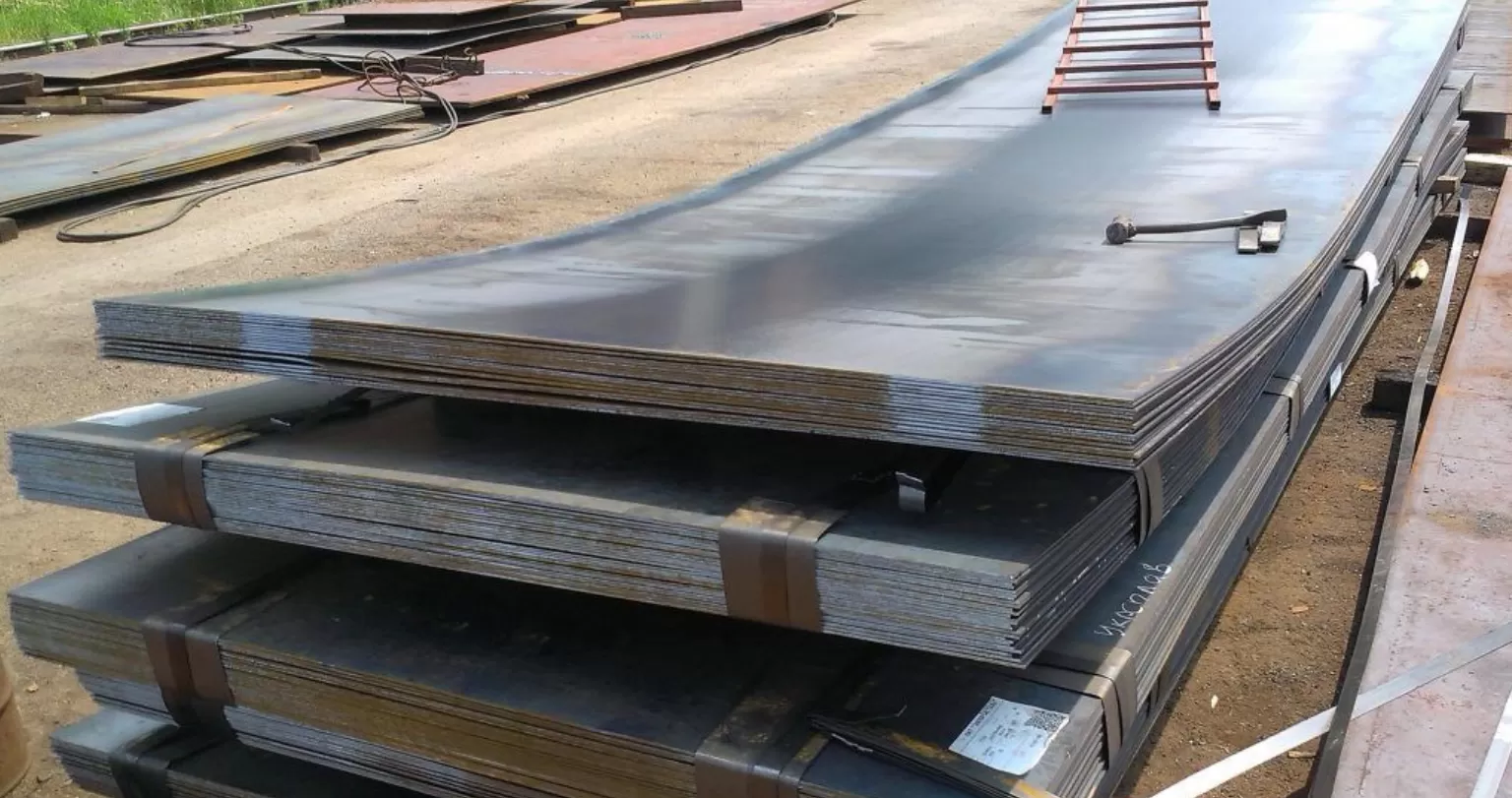

Renam Alloys Inc. is a leading company specializing in the design and manufacturing of S600MC High Tensile Steel Plates. These products are highly sought after in various industrial applications, especially in the automotive and manufacturing sectors. We produce high tensile steel plates using S600MC as the primary raw material, which is a low-carbon alloy that excels in forming operations. S600MC steel exhibits exceptional corrosion resistance and stress resistance, making it ideal for heavy-duty use.

Tensile and Yield Strength Properties

Our S600MC High Tensile Steel Plates offer impressive tensile strength, reaching up to 820 MPa, and a yield strength of 600 MPa. These plates also provide outstanding elongation properties, making them suitable for a range of applications. The structural and mechanical properties of S600MC steel, including elements like phosphorus, sulfur, silicon, manganese, and carbon, enhance the toughness, durability, and overall performance of the steel.

Dimensions and Thickness Variations

Renam Alloys Inc. offers S600MC High Tensile Steel Plates in a variety of thicknesses and widths. These steel plates can be manufactured in thicknesses ranging from 2mm to 1600mm, allowing us to meet a wide range of customer requirements. We adhere to internationally recognized specifications for S600MC, ensuring the highest quality in every product.

Applications and Versatility

S600MC High Tensile Steel Plates are particularly well-suited for use in load-bearing structures. These plates are available in various forms, including coils, slit coils, and strips. They are ideal for both forming and welding processes. The steel plates are designed to withstand wear and tear, providing durability and reliability in various operational conditions. Our production methods, combined with advanced machinery and rigorous testing procedures, ensure that these plates meet the highest standards of quality.

Temperature and Durability

Our S600MC High Tensile Steel Plates are designed to perform optimally at temperatures up to 580°C. Their resistance to wear and tear, coupled with their broad applicability in diverse industrial settings, makes them an essential component in various structural and mechanical applications.

EQUIVALENT GRADE

| S600MC EN 10149-2 Number:1.8969 | Comparison of steel grades | |

| SEW092 | QStE 600TM | |

| NFA36-231 | E620D | |

| UNI8890 | - | |

| ASTM | - | |

| BS1449 | 68F62 | |

Generally speaking, S600MC high tensile steel plates are made of high-strength, low-alloy structural steel that meets global standards. These plates possess a minimum yield strength of 50,000 ksi, making them ideal for various applications where strength and durability are required. Our commitment to precision ensures that we pay close attention to specific variations during production.

Manufacturing Process and Features

The plates are primarily produced using a hot working process, which is followed by annealing or heat treatment for improved mechanical efficiency. This process ensures that the steel avoids scaling in reducing environments and provides resistance to pitting and crevice corrosion, particularly in environments with high concentrations of halides and chlorides. After heat treatment, the plates undergo solution annealing and can be exposed to environments where chromium carbide precipitation may be an issue.

Formability and Fabricability

These plates are easily formable and fabricable with standard machines typically used for this grade of steel. Additionally, these plates perform well in reducing environments without requiring any post-weld heat treatment, making them versatile and efficient for various industrial applications.

Quality Management System

Our quality management system oversees the quality of both incoming and outgoing materials by conducting comprehensive raw material testing. We apply strict quality management at every step of the production process. Random checks are performed on each lot for both mechanical and chemical properties, and all tests are conducted in government-approved laboratories. Our heat treatment processes are closely monitored, and we use ideal fixtures and templates to maintain dimensional accuracy. Our products are periodically calibrated to global standards to ensure consistent quality.

Testing and Certification

Various tests are conducted on the S600MC plates, including chemical composition analysis, mechanical properties testing, hardness test, tensile test, positive material identification, and micro/macro testing. Other material tests include destructive and non-destructive tests, intergranular corrosion test, flaring test, flattening test, ultrasonic test, radiography, pitting corrosion test, and visual inspection.

Test Certificates and Documentation

S600MC plates are supplied with test certificates in compliance with EN 10204 3.1 or 3.2. These reports are certified by authorized manufacturers and include the product invoice, specification guide, fumigation certificates, and packing lists with details such as net and gross weight, quantity, and marks. Other included certificates are the raw material test report, mill test report, quality assurance plan, and heat treatment charts.

Packaging and Delivery

We supply fabricated S600MC plates in custom packaging or in large bundles, depending on the quantity of the order. Additionally, the plates are wrapped in plastic coatings to protect them from contamination during transportation.

Specifications

| Item | High Tensile Steel Plate - EN 10149-2 / WNR. 1.8969 |

|---|---|

| Standard | ASTM, ASME and API |

| Size | 0.5 mm – 200 mm |

| Thickness range | 2.4mm-16mm |

| Width range | 900mm-1850mm |

| Length | 2000mm to 12000mm |

| Process of Manufacturing | Hot-Rolled (HR) |

| Hardness | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

Chemical Composition

| Grade | C max | Si max | Mn max | P max | S max | AL max | Nb max | V max | Ti max | Mo max | B max |

| S600MC | 0.12 | 0.50 | 1.9 | 0.025 | 0.015 | 0.015 | 0.09 | 0.2 | 0.22 | 0.5 | 0.005 |

Mechanical Properties

| Grade | ReH-Minimun yield strength(Mpa) | Rm-Tensile strength(Mpa) | Nominal thickness(mm) | A-Minimum elongation Lo=5,65√So(%) | Nominal thickness(mm) | A-Minimum elongation Lo=Lo=80mm(%) |

| EN 10149-2 S600MC | 600 | 650-820 | From3 | 13 | to3 | 11 |

People Also Searched for S355J2G3 Plate

s600mc hot rolled structural steel plate, high tensile plate grade s600mc, s600mc high tensile steel plates manufacturer in india, s600mc en 10149-2 high tensile structural steel plates prices, s600mc high tensile steel plate mechanical properties, s600mc high tensile plate specifications, s600mc high tensile structural steel plate suppliers in india, s600mc high tensile steel plate manufacturers in mumbai, s600mc high tensile steel plates pdf, s600mc high tensile plate chemical composition, s600mc high tensile steel plate exporters in mumbai, s600mc high tensile plate stockists in india, s600mc steel plate exporter in india, s600mc high tensile steel plate stockholder in mumbai, high quality s600mc high tensile structural steel plates, s600mc high tensile steel plates in mumbai, s600mc structural steel hr plate, s600mc high tensile steel plate traders in mumbai, s600mc high tensile steel plates equivalent grade, s600mc high tensile structural steel plates, s600mc high tensile plate hardness, s600mc high tensile steel plates dealer in mumbai, s600mc steel plates in india, s600mc high tensile steel plates distributor, s600mc alloy steel plate, s600mc high tensile steel plate stockholder in india, s600mc high tensile plate equivalent, s600mc pressure vessel steel plate thickness, s600mc hot rolled plate, s600mc hr high tensile plate, s600mc pressure vessel steel plate in india, en 10149-2 s600mc steel plate material, s600mc high tensile plate properties, s600mc high tensile plate supplier in mumbai, s600mc pressure vessel steel plate weight, s600mc high tensile plate price list, s600mc high tensile steel plate stockists in mumbai.

We Offer Following Processing for S355J2G3 Plates

- Cutting

- Forming

- Drilling / Machining

- Grinding

- Testing

Applications of S355J2G3 Structural Steel Plates

- Machine building

- Pylons and other architectural structures

- Lifting and mobile equipment

- Construction of bridges

- Wearing plates

- Framework structures

- Crane booms

- Rail cars

- Stone or iron chutes

- Truck frames

- Containers

- Vehicles and transport equipment

- Steel constructions

- Anti-drill plates such as security doors, shot blasting equipment, and tumbling machine